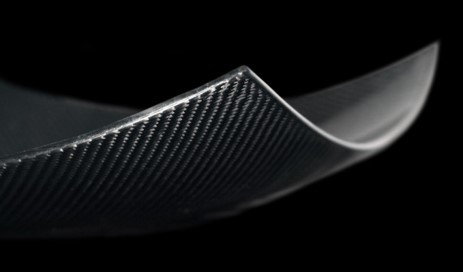

PREPARING SURFACES OUR SOLUTION The surface of the carbon, after component production, hardly receives the application of both paint and glue in preparation for the assembly to the other components. The surface of the parts is complex and not all areas are easily accessible; however, the surface to be painted/glued has to be uniformly prepared. When traditional mechanical methods, such as abrasive papers or the like are used, the operation can become extremely complex, if not impossible, and strictly depending on the ability of a few operators. Norblast has developed a surface treatment process specifically designed to process composites. High roughness means low performance; efficiency in energy production machines is an increasingly indispensable target. The reduction of surface roughness, obtained by vibratory tumbling, is a process that today requires processing times of several hours to achieve the minimum results required. Norblast has developed a work cycle capable of rapidly lowering the levels of roughness, allowing the vibratory tumbling cycle to be started with the initial value of roughness in the surface to be treated, which is already very close to the required target. With Norblast process, roughness total reduction time shifts from several hours to several minutes. The treatment can be carried out either manually or automatically up to a fully robotised solution.

This treatment creates a series of microscopic peaks and valleys on the surface of a component. This finish, and the roughness achieved, contributes to improving the adhesion of a subsequent coating of the component.

For this reason, the artificial change caused by the blasting of the surface is referred to as the “anchor profile”. Each coating requires an anchor profile with specific characteristics.

In general, thinner coatings require a “soft” anchor profile, while for very thick coatings the profile generated by sandblasting is usually deeper to increase the adhesion.

This creates the requirement for a specific “controlled sandblasting” treatment that allows set objectives to be achieved and maintained over time.

Our machines are designed and built to respond with maximum efficiency to the high quality levels required to successfully perform this special controlled sandblasting treatment.

The products dedicated to this specific treatment are equipped with control systems that can continuously monitor the underlying parameters for proper execution of the process, and to ensure its constancy and uniformity over time.CASE STUDY

Surface activation - composites

Thanks to our knowledge on the grits and of the most suitable shooting systems, it has been possible to design a series of systems capable of activating the surface, drastically reducing the limits deriving from the surface complexity. The process simplifies and reduces the risk of damage during the treatment. The treatment can be carried out either manually or automatically up to a fully robotised solution.Roughness reduction - energy generator blades