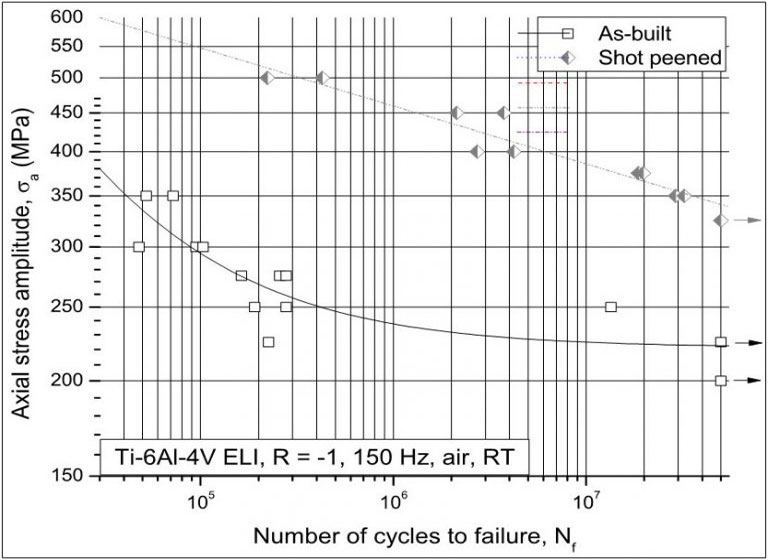

Treatment designed to improve the fatigue strength and to reduce the negative effects associated with the decarburisation of surfaces.

Shot peening is probably our leading treatment, the culmination of particularly thorough and detailed study by our research centre and our subsidiary Peen Service.

The treatment can reach a considerable depth and is often used to slow or eliminate breakage associated with stress corrosion, fretting and pitting, and to reduce the negative effects associated with the decarburisation of surfaces. In the aviation sector, it is also used before applying galvanic coating to eliminate the embrittlement caused by application of the coating layer.

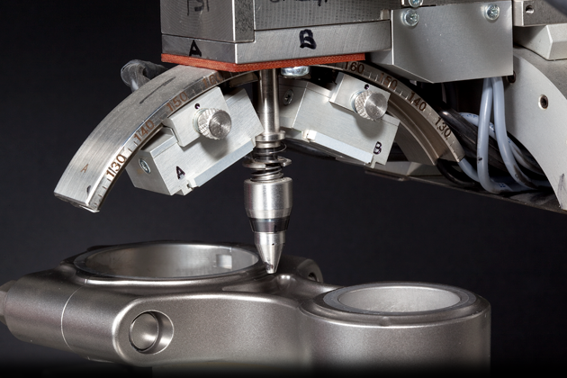

Almen intensity is a quantity through which we set up and manage the shot peening system.

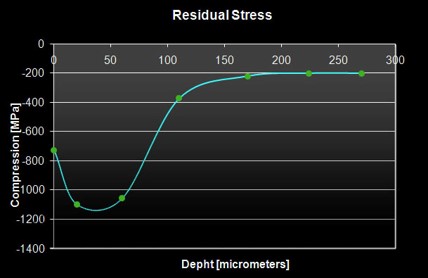

The residual stresses introduced through the shot peening process are measured directly on the treated component (destructive investigation!).

The residual stresses introduced through the shot peening process are measured directly on the treated component (destructive investigation!)

Go from this condition… …to this one.

… without intervening on the project with sometimes “painful” revisions.

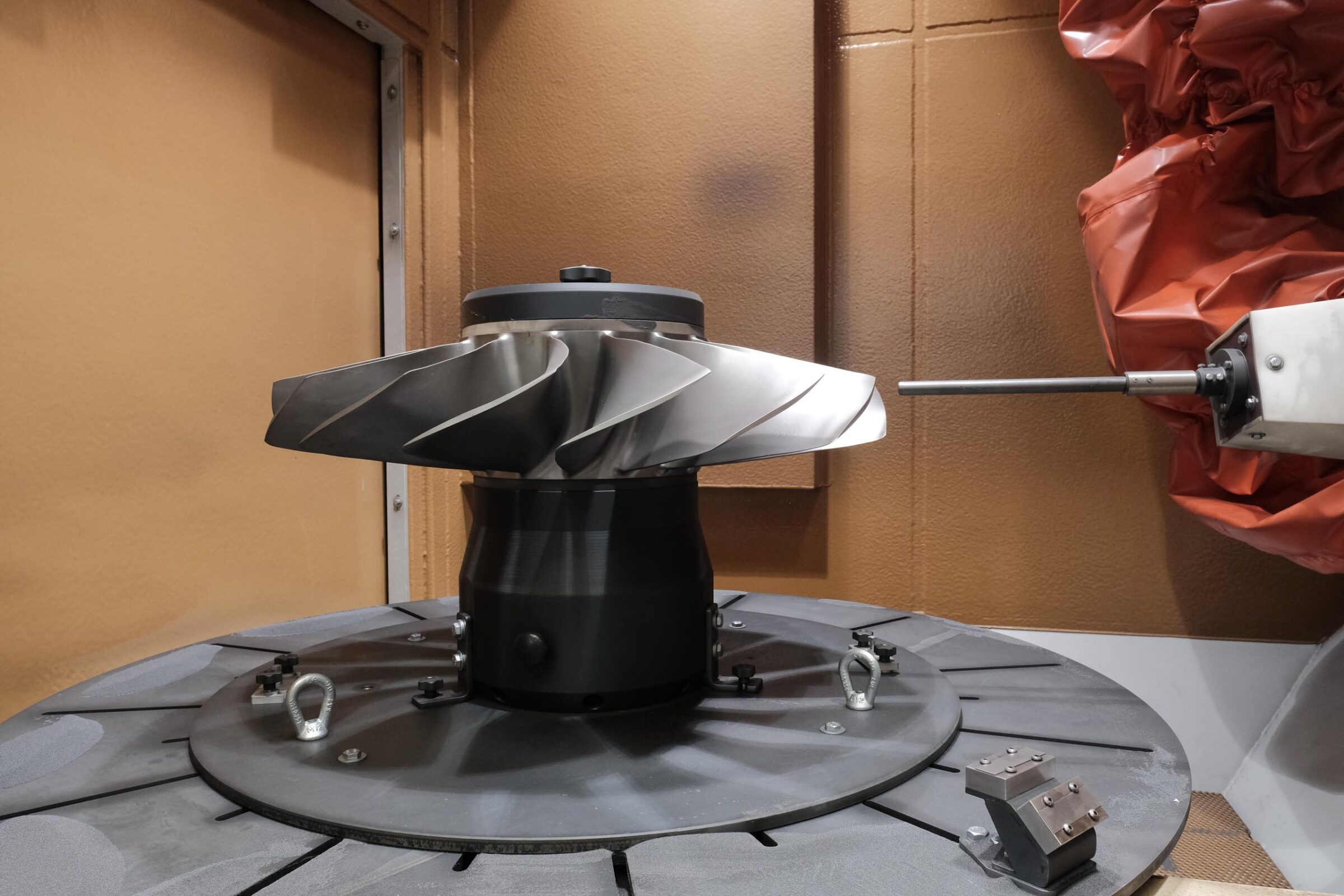

Our systems are designed with the highest technological contents to strictly respond to the specific needs of this particular treatment, characterized by numerous reference specifications and extreme application complexity.

Our machines are designed to give each single piece the same treatment, through the rigorous control of all the process characteristics such as the working pressure, the localization of the hot-spot, the angle of attack, the granulometry, the shape and capacity of the bead, the translation and rotation speeds of the various movements . Our solutions are fully compatible and certifiable according to NADCAP specifications and are compatible with the typical indications of the sector certifications.

Through Peen Service, our subsidiary specialized in shot peening, we can also offer, as appropriate, the outsourcing treatment on all components of this sector, both for fixed-wing and rotary-wing aircraft.