Competition in this industry is very high and strongly focused on process costs.

As a result, players seek to gain a competitive edge through process automation and optimization.

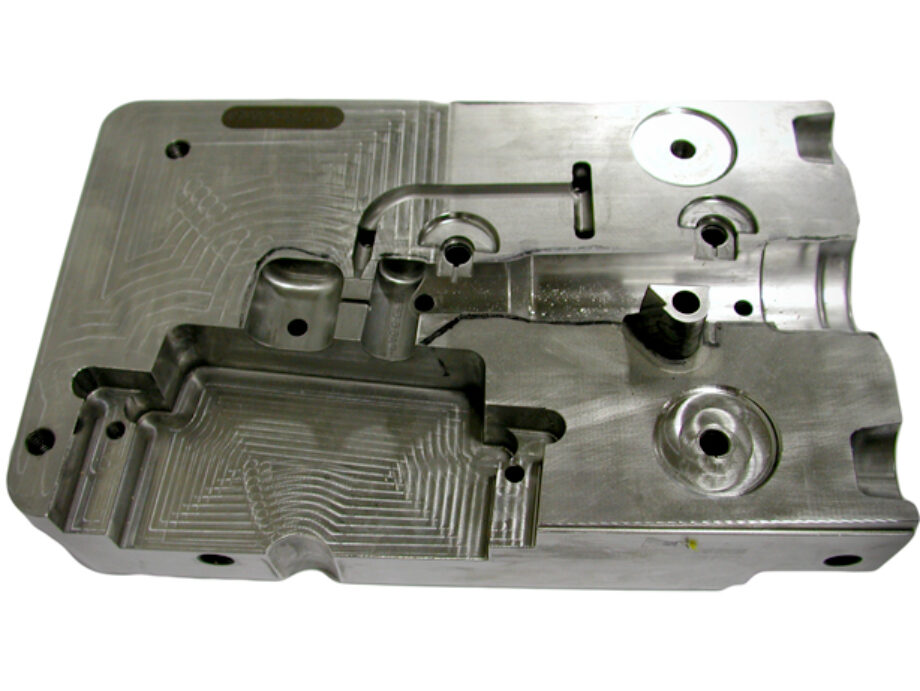

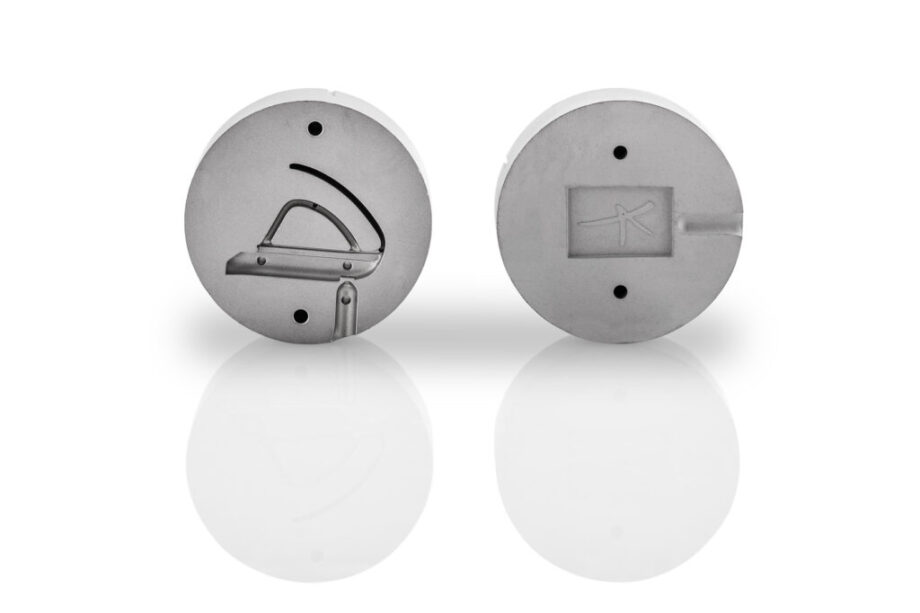

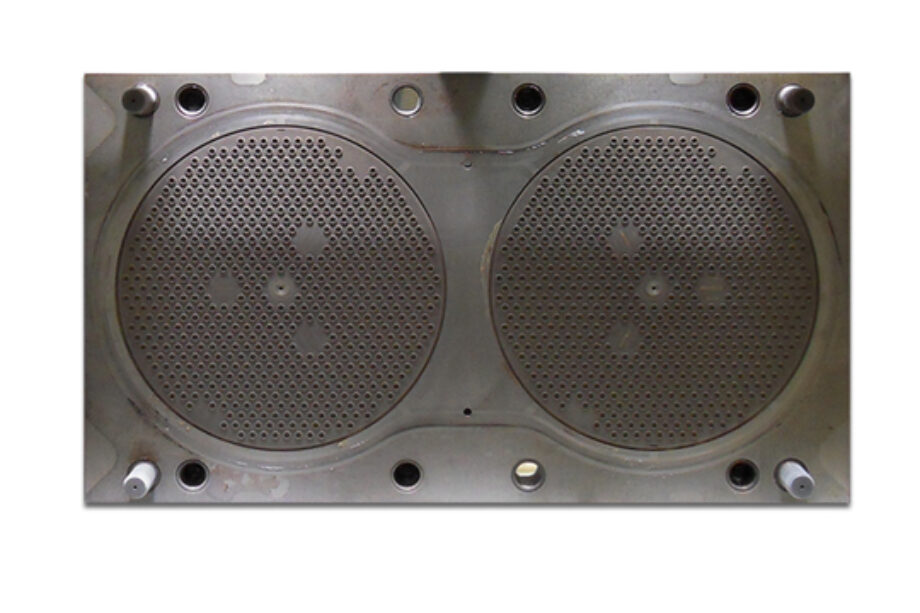

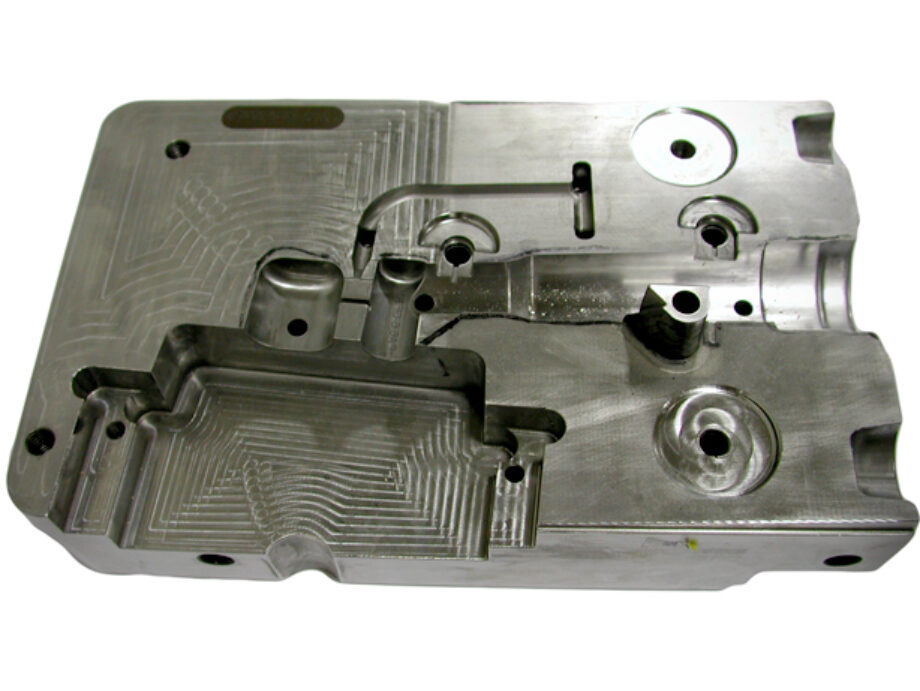

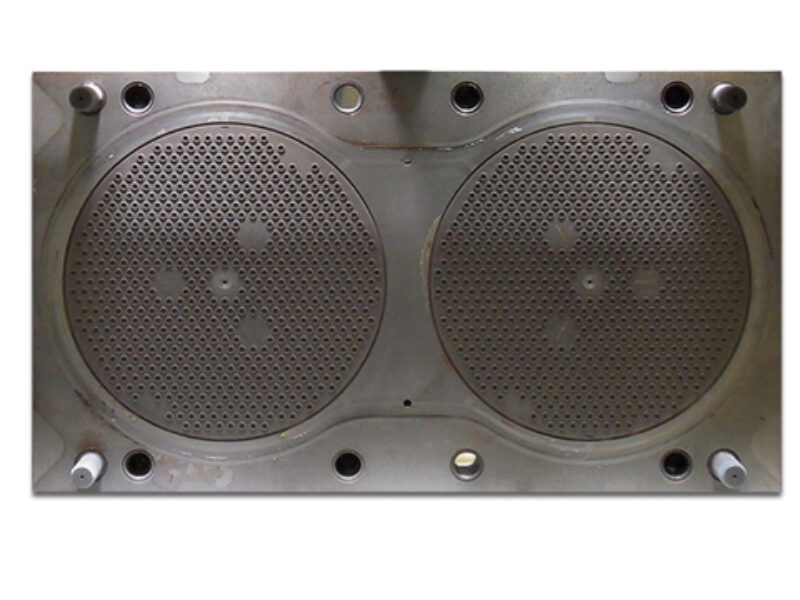

We are very familiar with the issues of mold machining and design our machines to provide fast, automated processes, so as to offer improved management of resources and production.