Controlled removal is the treatment used to uniformly eliminate small amounts of material from certain surfaces that have suffered deformation.

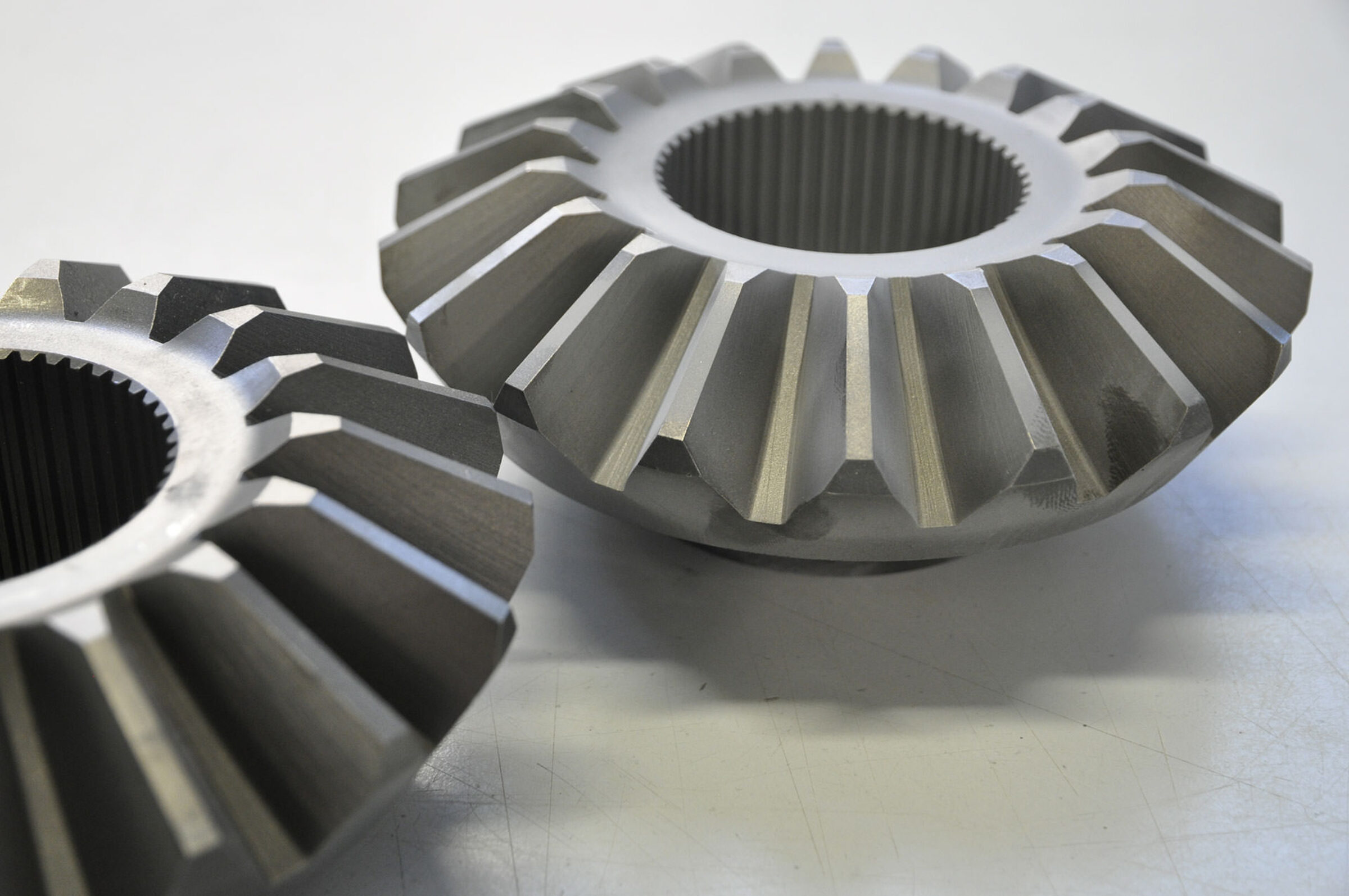

Frequently, mechanical components are irreparably damaged by heat treatments that cause deformation, by incorrect mechanical processes and by many other factors.

When this involves a finished, already heat-treated part, there is no other option but to discard parts that have undergone unacceptable deformation.

This generates significant costs and production delays. Our special controlled-removal technology makes it possible to restore the correct geometry of the part with targeted and effective operations.

This treatment can also be used for engravings or embossed effects and artistic creations in general.

According to the limits that the treatment must observe, Norblast proposes targeted solutions that can be implemented using manual machines or solely via automated applications.

Productivity targets can also be a major factor in identifying the most appropriate solution, but for this particular treatment, where quantities are not generally very high, identifying the main process parameters is fundamental, and particularly in the case of very strict limits, equipping the system with all the control and monitoring systems necessary for the proper execution of the “controlled-removal” treatment.