AT THE FOREFRONT OF INNOVATION OUR SOLUTION

Slag removal, finishing and aesthetic treatment achieved through the Inox Peen® process, developed and patented by our subsidiary Peen Service, fully meet HACCP standards as well as the cleanability requirements for stainless steel.

Our in-depth knowledge of processes and materials enables us to design ultra-efficient machines that guarantee top-quality results.

For stainless steel, for instance, our patented Inox Peen® treatment lends treated surfaces a particular roughness profile that achieves the same cleanability as a BA polished surface or better.

This is especially important in the food, chemical, biomedical and pharmaceutical industries.

To guarantee the quality of the Inox Peen® treatment, we have developed a special technique that is very similar to shot peening, turning this treatment a truly unique process. The Inox Peen® process gives surfaces excellent aesthetic qualities, with high resistance to fingerprint marking, and ensures the highest sanitization capability.CASE STUDY

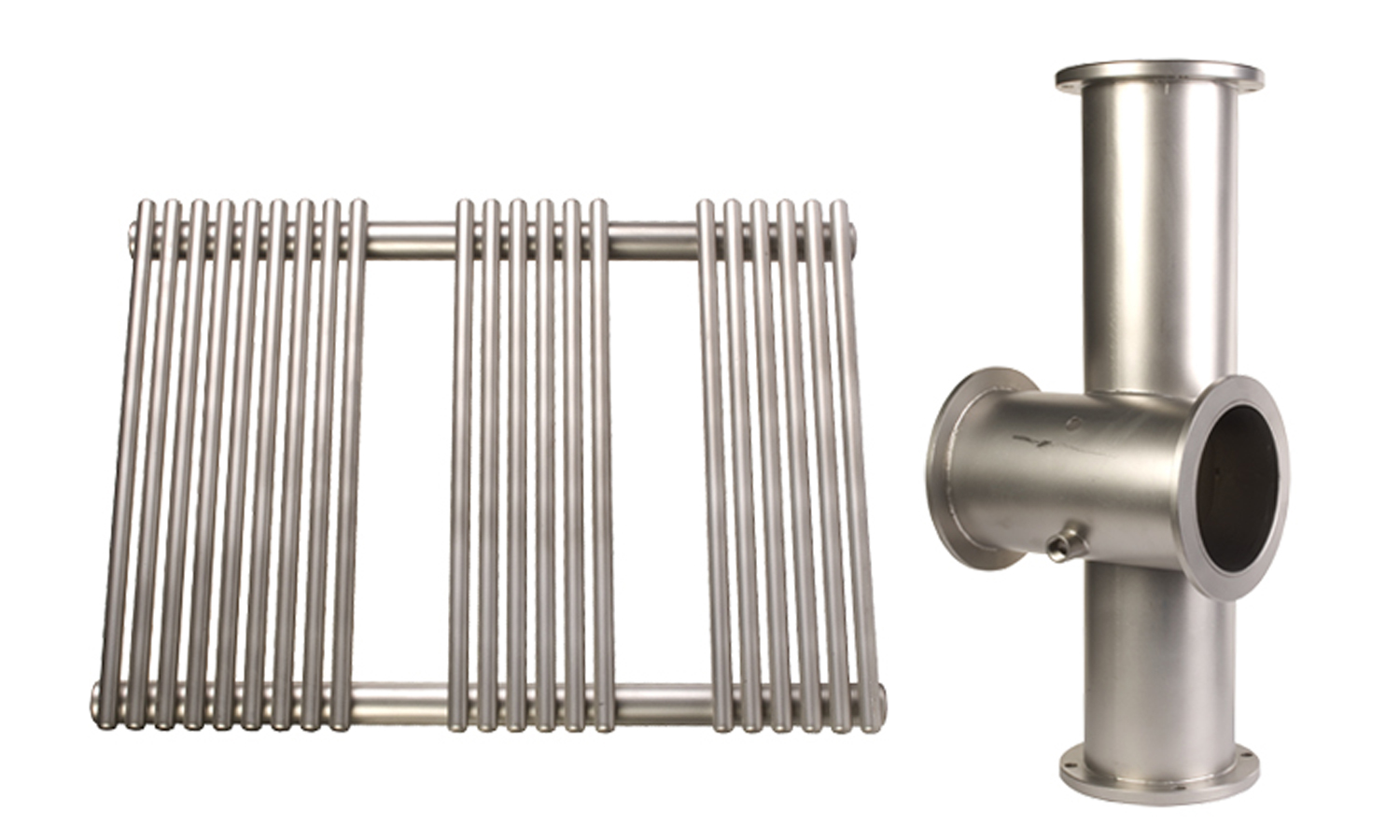

Inox Peen Treatment