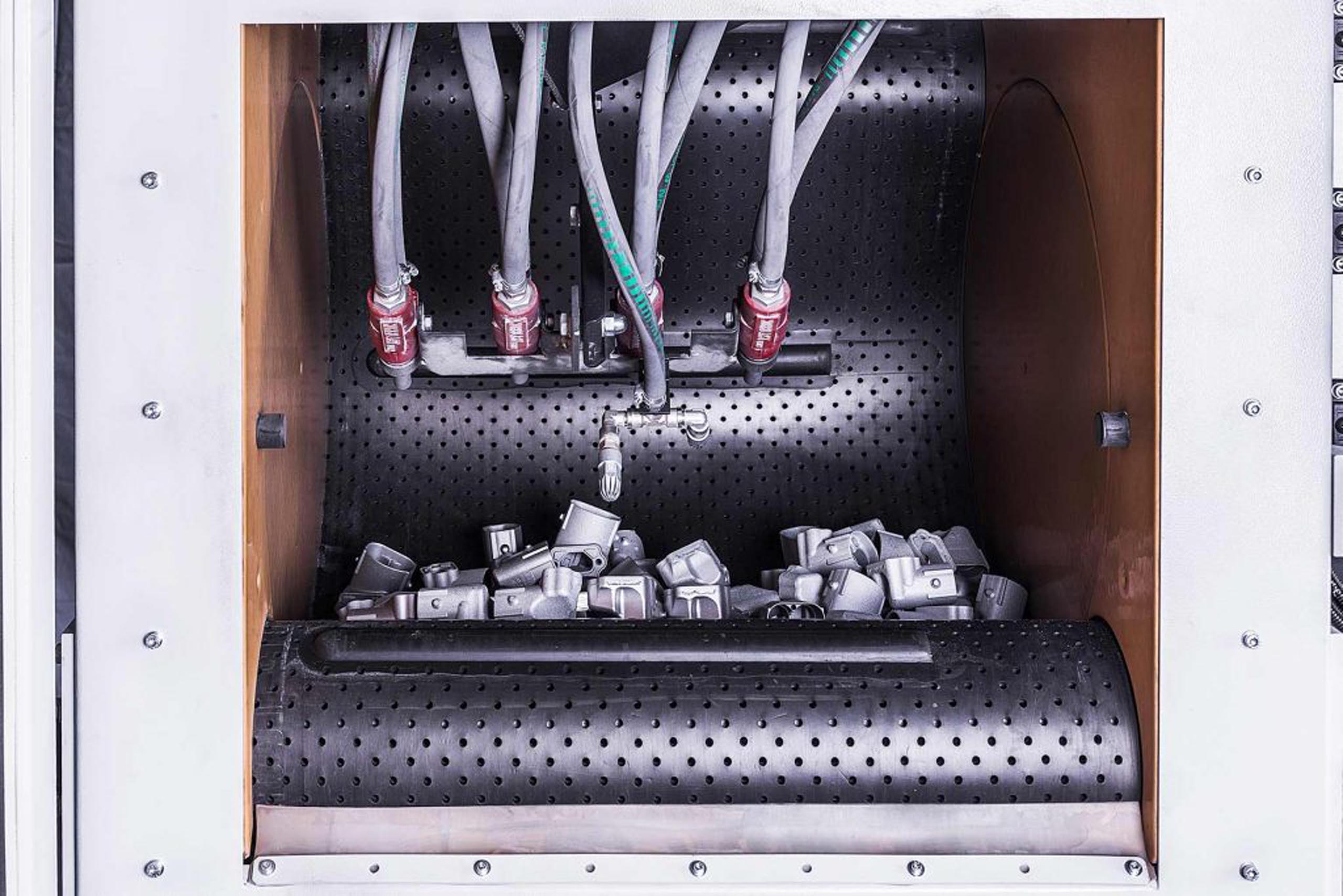

SANDBLASTING MACHINE FOR ADDITIVE 3D7

Work Chamber Dimensions

620 x 600 x 500 mm

Max loading capacity

25 kg

Propulsion system

Venturi