Designed specifically for dyeing parts made with Additive Manufacturing Technology, the new 3DWave machine is the ideal solution for achieving outstanding results and maximizing productivity.

High production

Rotating basket

450 mm x 300 mm x 300 h

The innovative dip dyeing system ensures precision and uniformity of coloring. 3D WAVE becomes the right ally for companies working with 3D technology and needing an efficient and reliable machine.

Easy to use: automatic process without intermediate manipulations

Customizable programs: easy to create tailored to your needs

Toward Industry 5.0: 3DWave analyzes and stores daily power consumption and thus allows you to perform consumption-saving and optimization activities

The parts are placed inside a stainless steel mesh basket. The lid of the basket is equipped with a locking system at different heights that prevents the pieces from falling out and ensures their integrity during rotation.

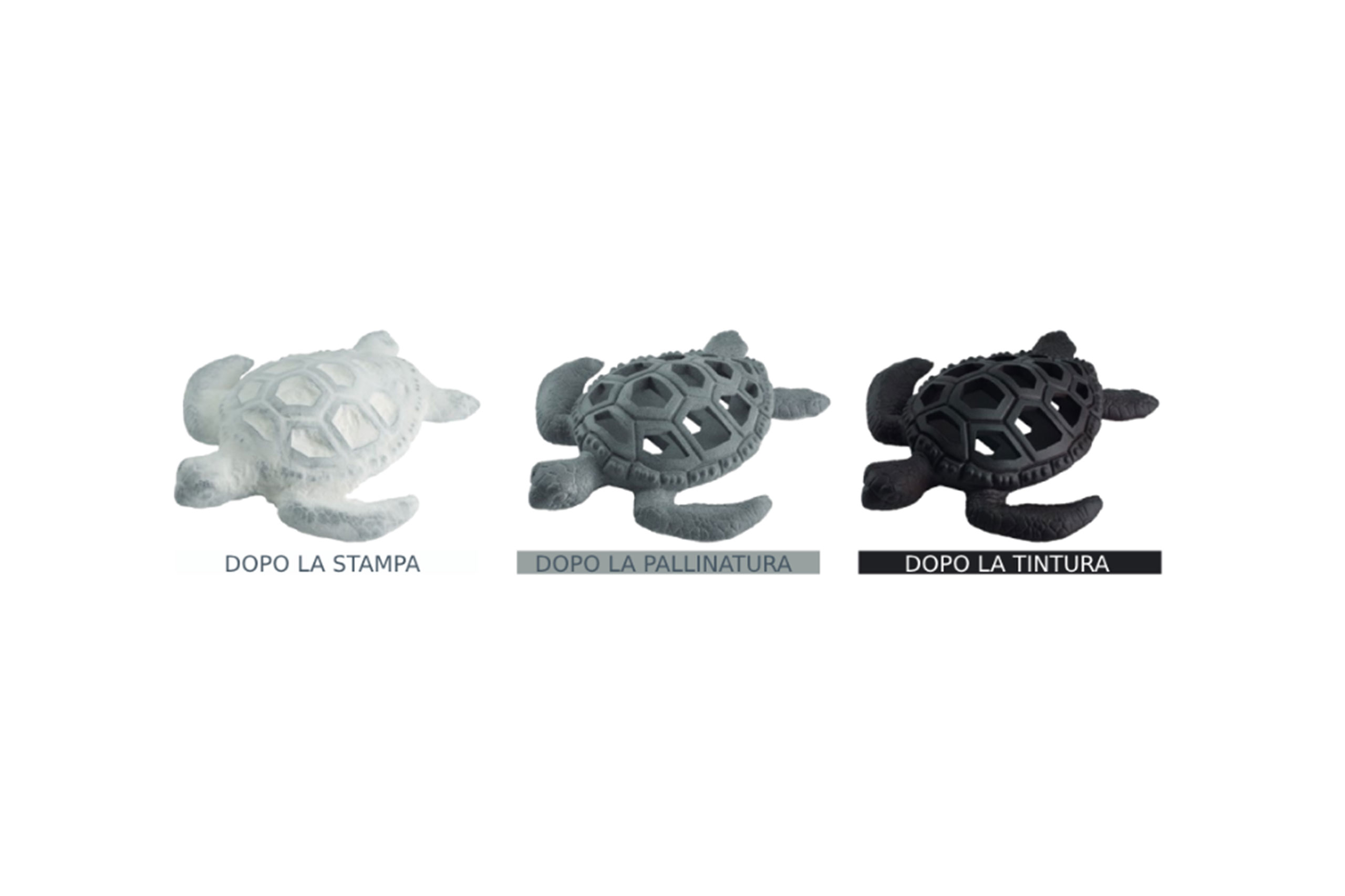

Thanks to RotoWave technology, by means of partial immersion and continuous changeover, the liquid moves constantly while entering even deep cavities, improving the ability of the dye to adhere to surfaces, avoiding stagnation and halos. The machinery, with its flexibility in creating customizable programs, allows an automatic process without intermediate manipulations.