Wide range of solutions for manual handling of small, medium and large sized parts

Choosing Norblast means partnering with a company that not only supplies top-notch machinery, but also enhances production processes through continuous technological research and expertise, reducing costs and improving product quality.

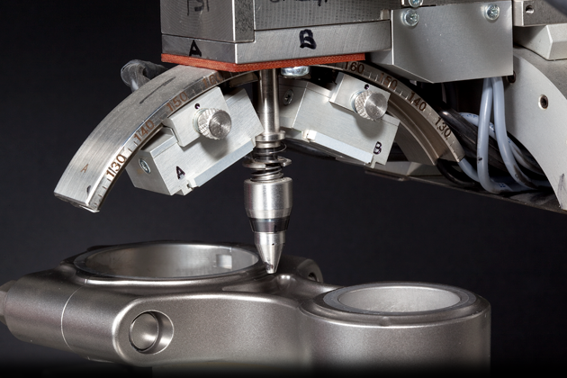

A wide selection of manual and automatic systems for parts of all sizes. Our venturi or direct pressure systems are engineered to meet any industrial sandblasting and shot peening requirement.

Wide range of solutions for manual handling of small, medium and large sized parts

High productivity automatic machines able to guarantee the highest process repeatability

Custom-designed line for the post-processing of components made with Additive Manufacturing technology

Custom-designed line with biocompatible components, to meet the high requirements of the biomedical sector

Thanks to our expertise and willingness to engage in research, we can identify the ideal solution and develop a tailor-made productive design

At our Norblast LAB Research Centre, we work with you to develop the most suitable finishing solution, guaranteeing the desired outcome.

We design and custom manufacture our sandblasting machines and systems to match our customers’ specific needs and goals.

For us, accompanying the customer from the start-up to the after-sales phase is a commitment as important as guaranteeing the quality of our products.

Our Norblast warehouses stock a comprehensive range of spare parts for sandblasting and shot peening machines, including guns, nozzles, filter cartridges, gloves, grits, and hoses.

At our Norblast LAB Research Centre, we carry out specific tests on your components. These Tests offer dual benefits: they allow you to evaluate the effects of the surface treatments, and help us identify and resolve any critical process issues.

In order to meet your needs precisely and efficiently, we guide you through every stage of the project, offering reliable technical support and laboratory testing to validate each solution presented.

The Peen Service offers “controlled shot peening” services for external clients. The team routinely uses their machines for complex operations, gathering valuable insights that help continuously improve our machine design.