THE CHALLENGE OF EVOLUTION OUR SOLUTION The aim: to obtain roughness on a screw to favour bone integration The screws for implantology must allow for safe and firm anchoring between the mandible and metal. For proper bone integration, the surface of the screw must have a controlled roughness. In addition, screws for dental implants must be of a high quality, bio-compatible, hygienic and safe. The client uses both stainless steel and titanium. The challenge: to create a special compact machine for the processing of implantology components The client asked us one single automatic machine with which to treat both stainless steel and titanium components. The machine must ensure process continuity and repeatability and must conform to international regulations and bio-compatibility standards. A compact machine was designed that can adapt to the client’s production area. Norblast solution: Strengthened by our experience in the biomedical sector, we built a special machine dedicated to the implantology sector that respects all international bio-compatibility standards. All of the machine’s materials (structural work, components, coatings) are traceable. The stainless steel is certified and the machine ensures non-contamination of the product. The controlled roughness process is carried out thanks to automatisms and ensures a measurable and repeatable result. The particular structure of dental sector components requires a special machine to strictly control all processing parameters. We created an automatic sifting system to keep the grit value constant and ensure the profile of the component after hundreds of cycles. The motor can manage different grit sizes within the same cycle. In addition, the machine can alternate between different materials without mixing them. Stainless steel or titanium components for prostheses can be produced without interference. The advantages of the Norblast special machine: The client has increased productivity and gained fixed production times thanks to the automatic machine. With one single machine it can manage components of different materials. The repeatability of the process is guaranteed by the automatisms, that can manage the work parameters set by the operator. Thanks to its experience in the biomedical sector, certified by the supply of machines to key companies in the sector, the client has been able to acquire a machine that respects all bio-compatibility standards. Norblast has provided the machine and taken care of all documentation needed to certify the compliance with international regulations.

The components processed are for use in the human body. In this sector, a global vision is required.

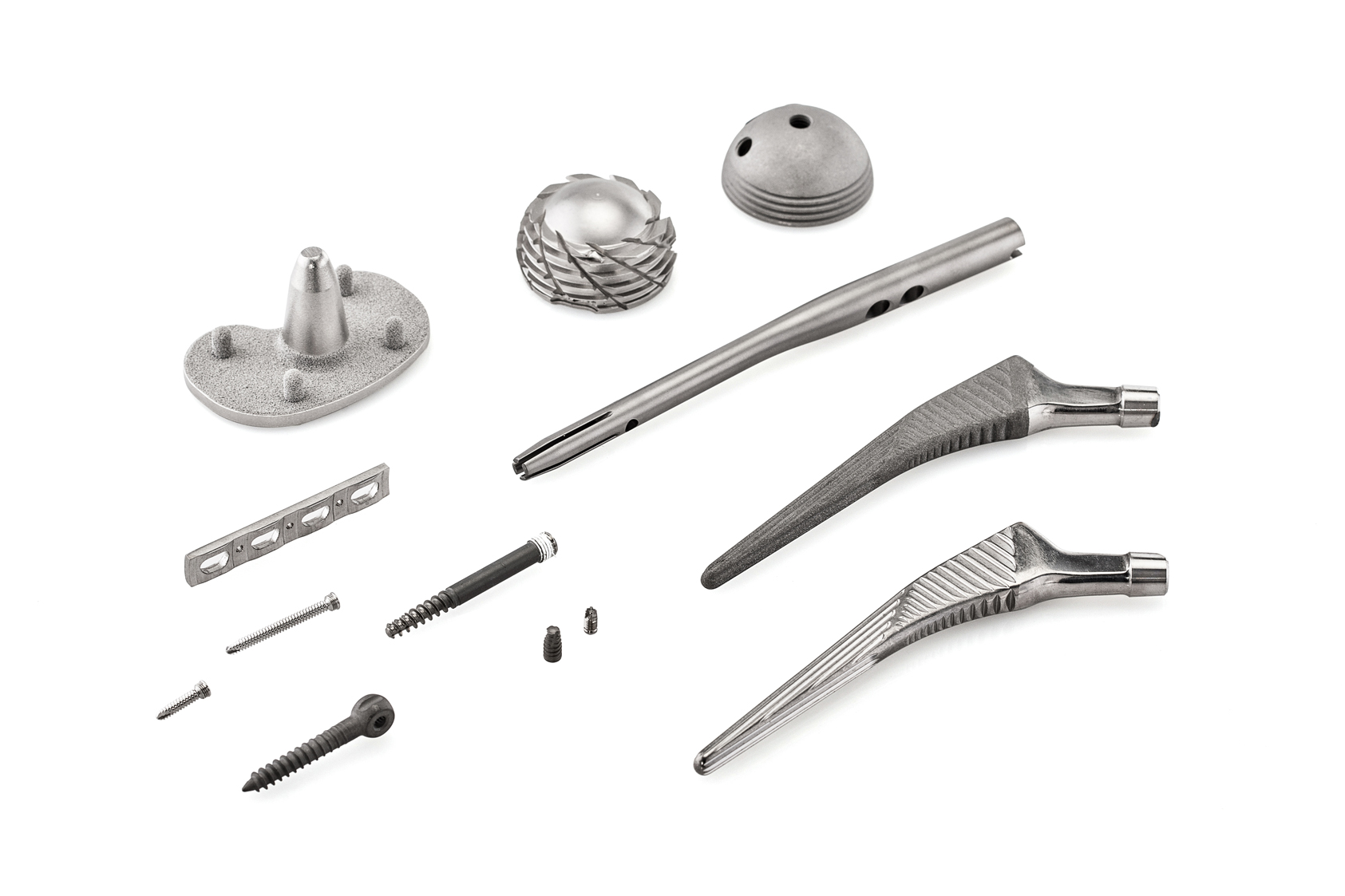

Our Hi-tech sandblasting machines ensure that controlled roughness is achieved for the osseointegration of limb prostheses or dental implants. Total process control ensures reliable, consistent results for each individual component processed.

Our shot-peening machines are designed to guarantee maximum mechanical strength and durability.

In this sector, a global vision must be combined with full biocompatibility. To eliminate any risk of components being contaminated during treatment, our machines are designed with certified biocompatible components.

Whatever the field of application, our machines incorporate our in-depth understanding of processes and our ability to offer the highest levels of automation and productivity.CASE STUDY

Osseointegration of dental implants