Shot peening is our leading treatment, the culmination of particularly thorough and detailed study by our research center and our subsidiary Peen Service.

This treatment is designed to improve the fatigue strength of cemented, nitrided and reclaimed parts. The treatment can reach a considerable depth and is often used to slow or eliminate breakage associated with stress corrosion, fretting and pitting, and to reduce the negative effects associated with the decarburisation of surfaces.

In the aviation sector, it is also used before applying galvanic coating to eliminate the embrittlement caused by application of the coating layer.

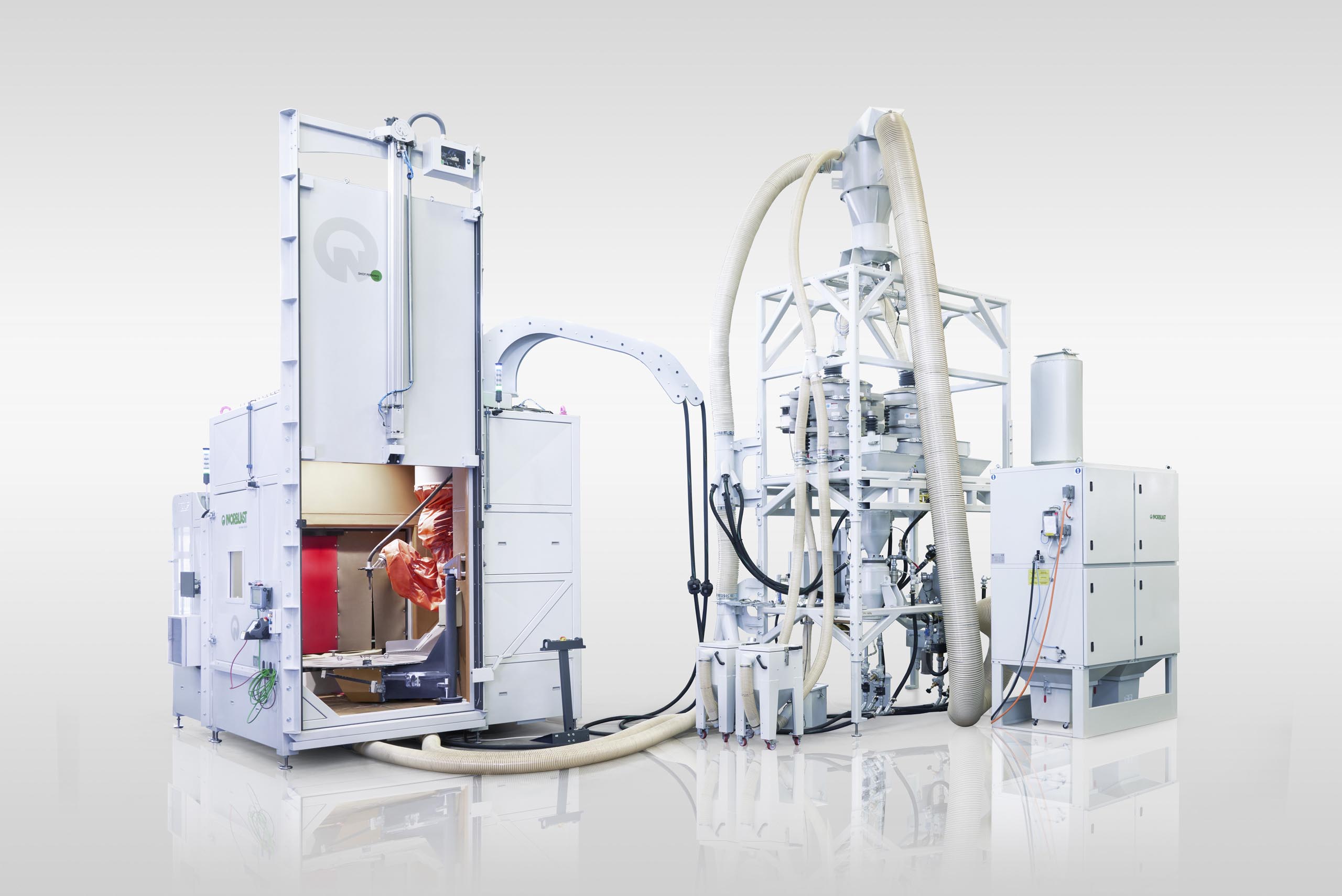

Our systems are designed with the most advanced technology to completely satisfy the specific requirements of this particular treatment, characterized by numerous specifications and extreme application complexity.

Our machines are designed to give every single piece the same treatment through rigorous control of all process characteristics, including working pressure, hot-spot location, blasting angle, shot size, shape and flow, and the speed of shifting and rotation of the various drives. Our solutions are certified under NADCAP specifications and are compatible with typical guidelines of industry certifications.

Where applicable, our specialized shot-peening subsidiary Peen Service also offers outsourced treatment of all components for this sector, both for fixed and rotary-wing aircraft.