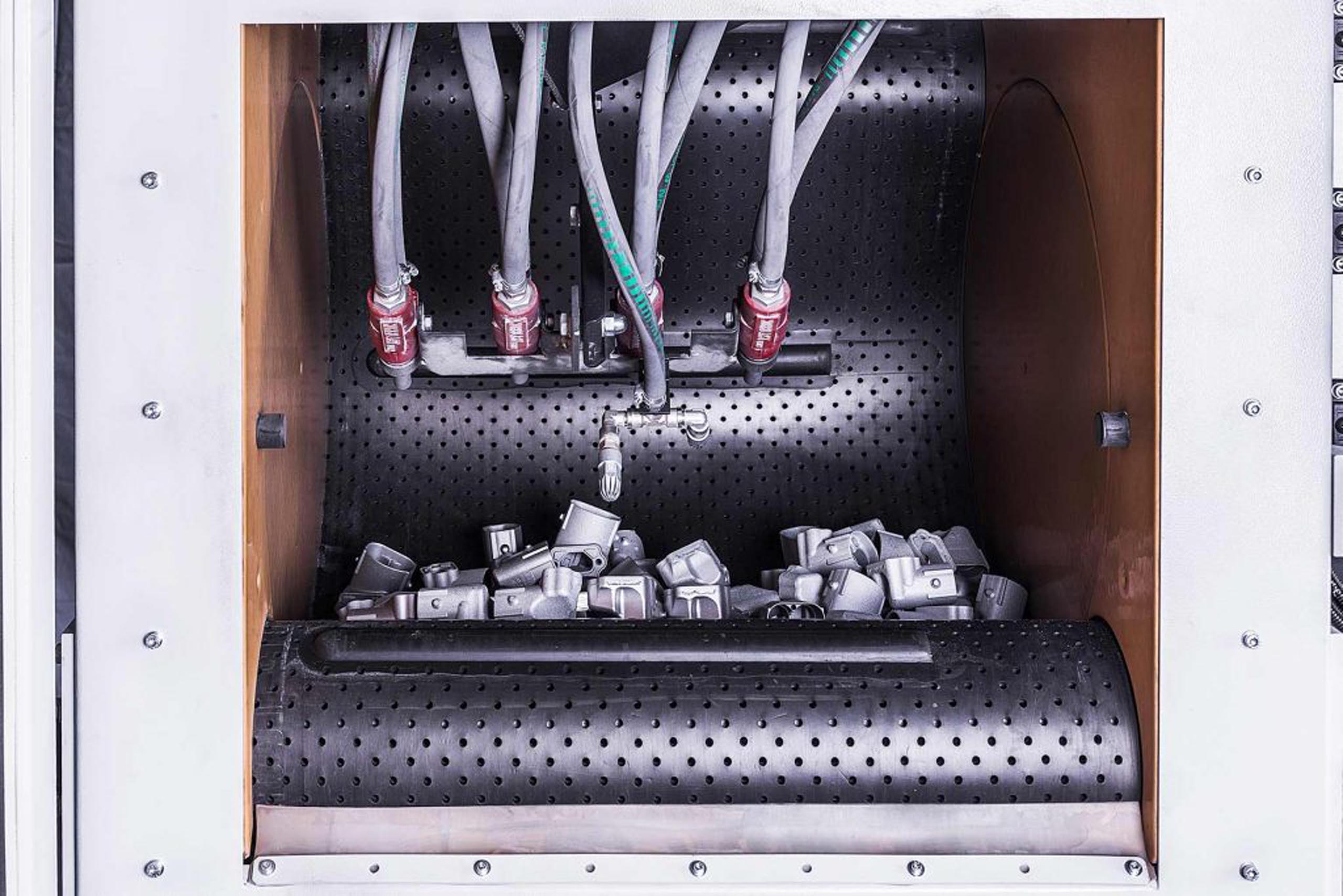

The 3DBelt is the flagship model of our 3D-Printing Line. A Sandblasting Machine designed for automatic post-processing, for high production batches made with Additive Manufacturing technology.

Four guns powered by a horizontal motion combined with the belt rotation will provide optimal surface coverage, ensuring process repeatability.

High Production

Rotary Carpet

30 kg

The abrasive selection and recovery operations take place automatically by means of a suitably sized cyclone system, which conveys the crushed grit and waste dust to the filter.

It can also integrate the innovative Ion-Cleaning system to reduce any electrostatic phenomena in the case of treatment on plastic parts, such as PA12.

The 3DBelt machine is equipped with a PLC to manage sandblasting recipes and scheduled maintenance activities. It can also be equipped with an automatic loader, compatible with Industry 4.0