Industrial sandblasting machines with pressure systems:

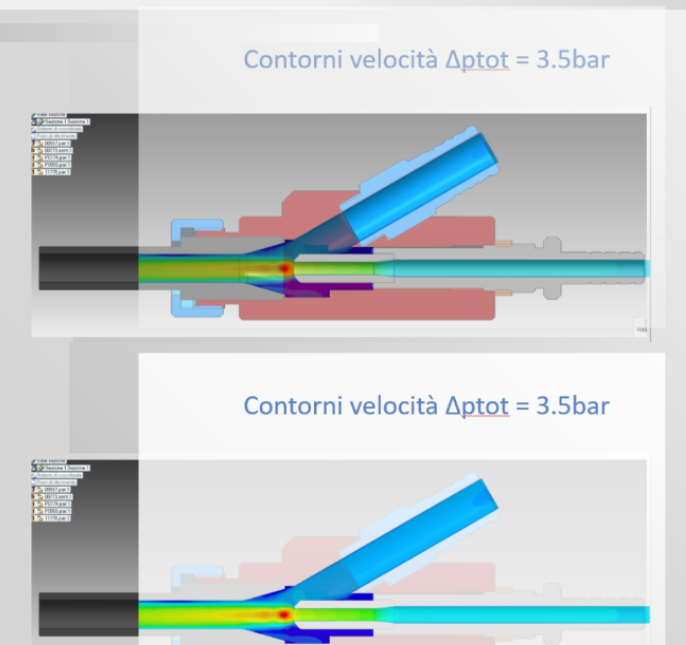

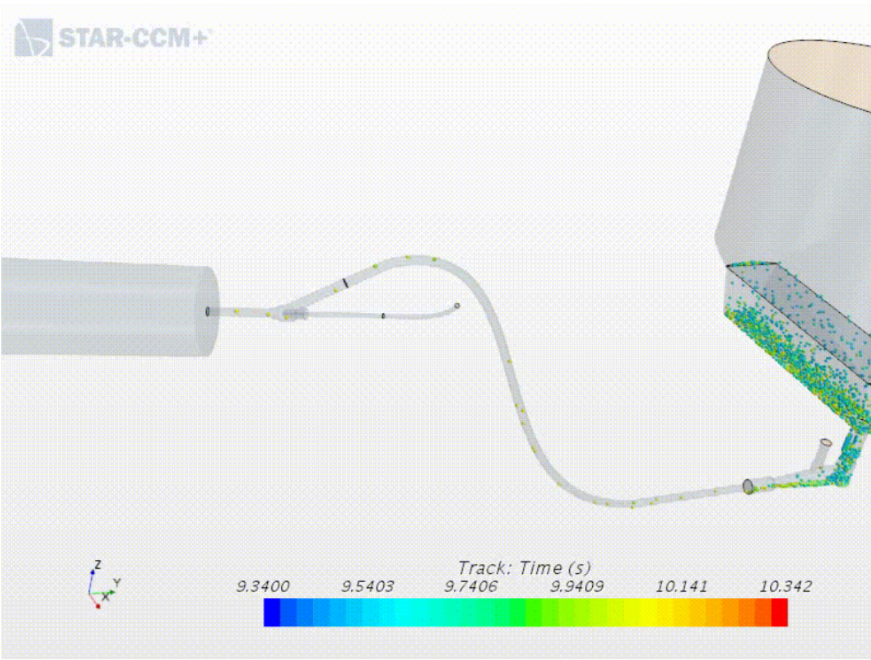

Norblast pressure sandblasting machines, on the other hand, work by pushing material – angular or spherical – from the pressure tank that is fired directly onto the workpiece. Thanks to a specific valve system, it is possible to balance both the grit flow rate and the compressed air pressure, thus achieving a machining process focused on the actual need; this makes machining even more precise and faster than with vacuum systems.

But how to decide whether to use sandblasters with vacuum systems or sandblasters with pressure systems?

Despite the fact that both of these machines serve, in essence, the same task – the size of the workpieces to be processed and the different processes to prepare them for further processing – they differ greatly in terms of performance and final output. In fact, pressure systems are able to handle larger volumes, in less time and with more precision, due to the greater number of variables available to control. However, it must be considered that, precisely because of their high precision, they are more complex to handle, require more plant components and have higher operating costs due to a need for more maintenance and higher energy consumption. However, it must be considered that the higher production capacity often justifies the greater burden. On the other hand, the vacuum system is cheaper, simpler to implement, not as fast and supports a less extensive processing range.

Which industrial sandblasting machine to choose?

Both types have their own advantages. So to understand which type of sandblasting machine is right for you, it is necessary to define the type of machining and precision required. At Norblast, we recommend the use of vacuum system machines, whenever the treatment required makes it productively advantageous. This is because they are more immediate in terms of ease of use, maintenance and consumption, both with regard to quantity of grit and compressed air. Instead, we recommend opting for pressure systems in case of large surfaces to be processed, reasons intrinsic to the workpiece to be machined, cramped areas to be reached, particularly dirty/crusted/oxidised components to be processed, including shot peening treatment. It is understood that both pressurised and Venturi systems are compatible whenever specific quality standards are required, where safety parameters must be met, such as in the medical and biomedical, aeronautical and automotive sectors, where precision and machining of components demand excellent output quality.