Treatment suitable for eliminating shavings on components processed with machine tools, as well as burrs from stamping metal and/or plastics.

Deburring has always been one of the main problems of turneries. Even modern technology, despite advancements in machines and cutting tools, has still failed to completely resolve this annoying problem.

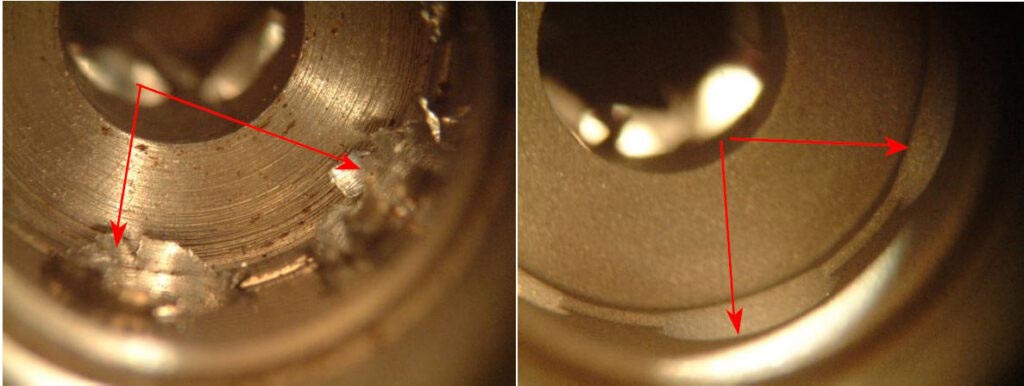

Deburring means eliminating shavings on components processed with machine tools, as well as burrs from stamping metal and/or plastics, although in this latter case their formation is due to leakage of material from poorly sealed areas or gas leaks.

In short, the task is to remove unwanted material that is still attached to the machined part.

Burr removal is generally a rather labor-intensive and complex task.

With conventional technologies the presence of threading, small holes, non-standard joints, grooves that are difficult to access or particularly complex shapes requires the expert touch of one or more operators with very long processing times.

Another currently widespread issue makes the situation even more challenging. Medium-large companies are increasingly focused on product differentiation and just-in-time supply systems requiring a series of small lots in a short time, and of course at low prices.

A lengthy process that requires significant manual labor cannot meet these demands.

Compressed-air sandblasting becomes an irreplaceable solution for deburring.

Manual and automatic/flexible systems (depending on the productivity required) can continuously and very rapidly remove unwanted material.

Special applications make it possible for our systems to perform compressed air deburring in areas, channels and joints that are not accessible with conventional systems.