The foundry industry is developing continuously. In order to respond effectively to market demand, castings must not simply be well made, but must also be delivered well cleaned and finished.

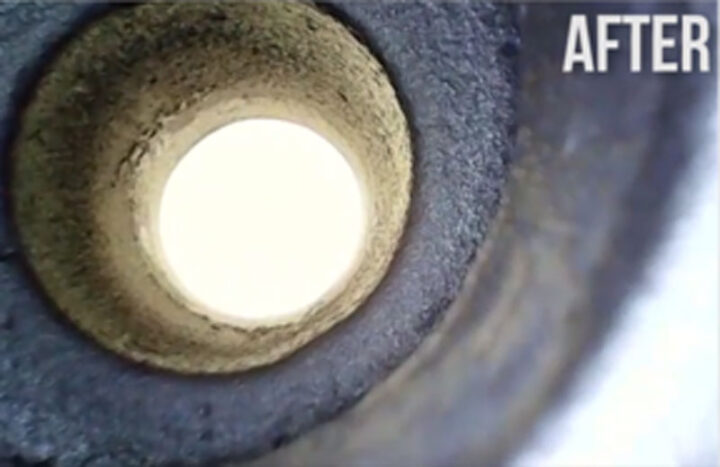

The residual removal within the channels is an explicit request of the end user.

If such residues were to circulate inside the system during its final use, they could lead to damage and production stop of the entire machinery.

To meet the demand for higher cleaning quality, the process often requires a double treatment; first high-pressure blowing and then dedicated shot-peening. So far, these phases have been carried out manually, in two distinct times with different nozzles and in dedicated machines.

Norblast designed a solution to perform both high-pressure blowing and dedicated shot peening inside the same cabin and within the same process stage.

Inside the cabin the robot provides a preliminary roughing treatment with compressed air, and, with no operator needed, changes the nozzle automatically and also provides finishing until the complete removal of residues inside the casting.

The casting change time has only a marginal impact on the production cycle as it is carried out during the process phase. This solution is designed to be integrated into a 4.0 production logic.