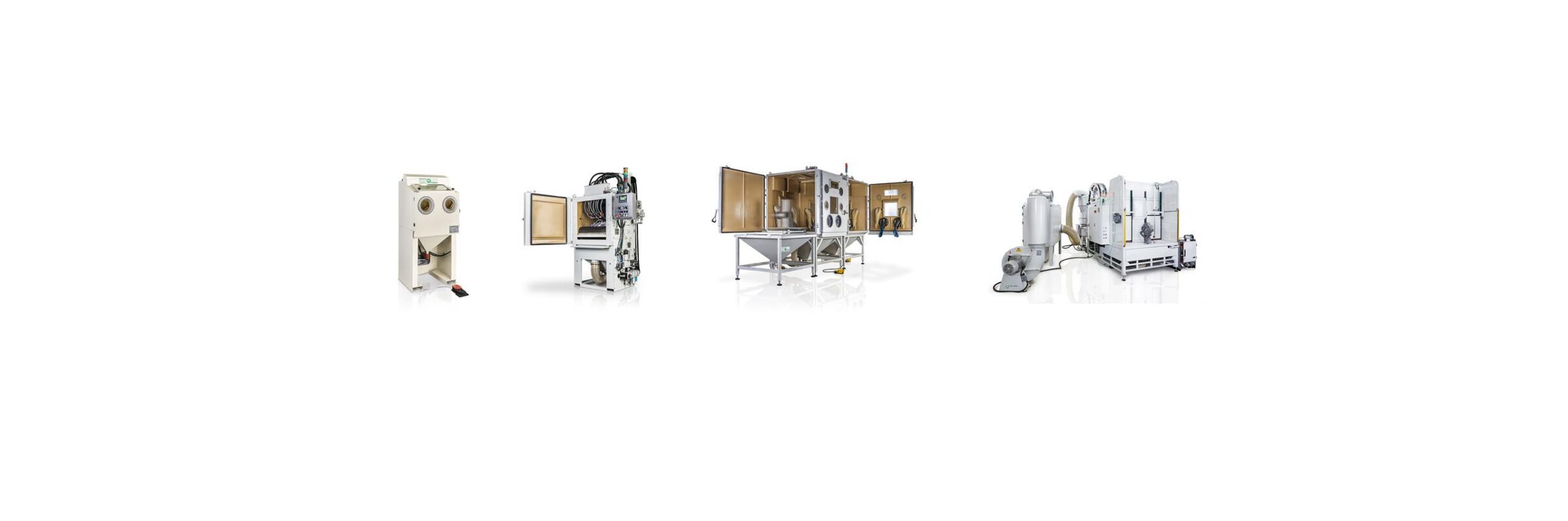

Wide range of solutions for manual handling of small, medium and large sized parts

Designed for your needs, tested on our experience. We believe that each company is a reality in itself and this is wht we design our sandblasting and shot peening machines, deepening your expectations, the area of use and the field of application.

Our machines are born for you, based on your specific needs and the experience we have gained by producing more than 7000 sandblasting and shot peening machines, tackling problems of all kinds.

We produce six shot peening and sandblasting machine lines of different types and capacities to meet different market requirements.

With just a few clicks you will find the right machine for your surface treatment needs!

Wide range of solutions for manual handling of small, medium and large sized parts

High productivity automatic machines able to guarantee the highest process repeatability

Custom-designed line for the post-processing of components made with Additive Manufacturing technology

Custom-designed line with biocompatible components, to meet the high requirements of the biomedical sector

Thanks to our expertise and willingness to engage in research, we can identify the ideal solution and develop a tailor-made productive design

See more information on SURFACE TREATMENTS here:

Our shot peening and blasting machines are designed to achieve high quality surface treatments, high productivity and repeatable processes such as: