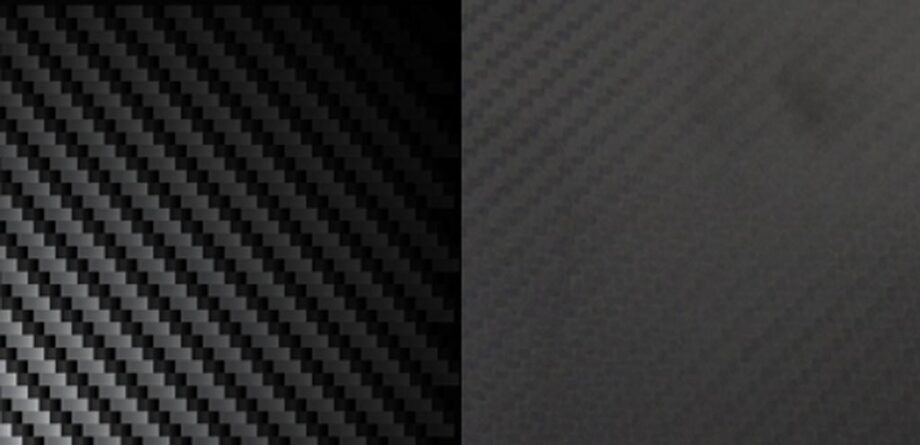

Sandblasting for surface activation on carbon fiber and composites

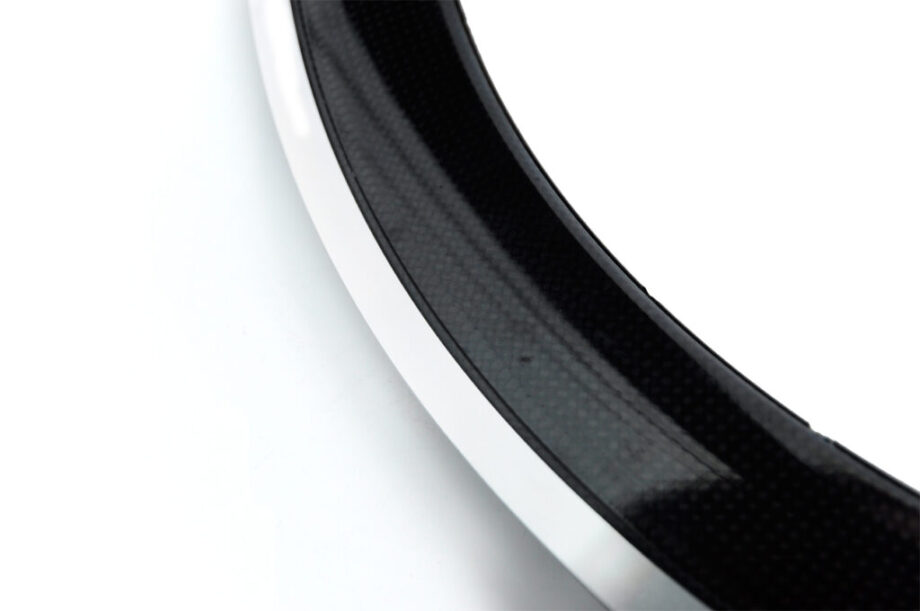

Laying paints, gluing additional components or depositing coatings on carbon or other composites requires a surface pre-treatment of the artefact called surface activation.

Surface activation can be performed in different ways.

In the past, the most common alternative was manual surface preparation, whereby an employee would treat the component using sandpaper (scotch brite methodology).

As can be easily guessed, this methodology presented the Company with several critical issues.

Firstly, the manual processing times are extremely long. Secondly, the success of the processing depends heavily on the skills of the operator (who must always guarantee good manual dexterity throughout the production cycle). Finally, manual surface treatment is particularly difficult if the component to be treated has complex surfaces (undercuts or precision details).

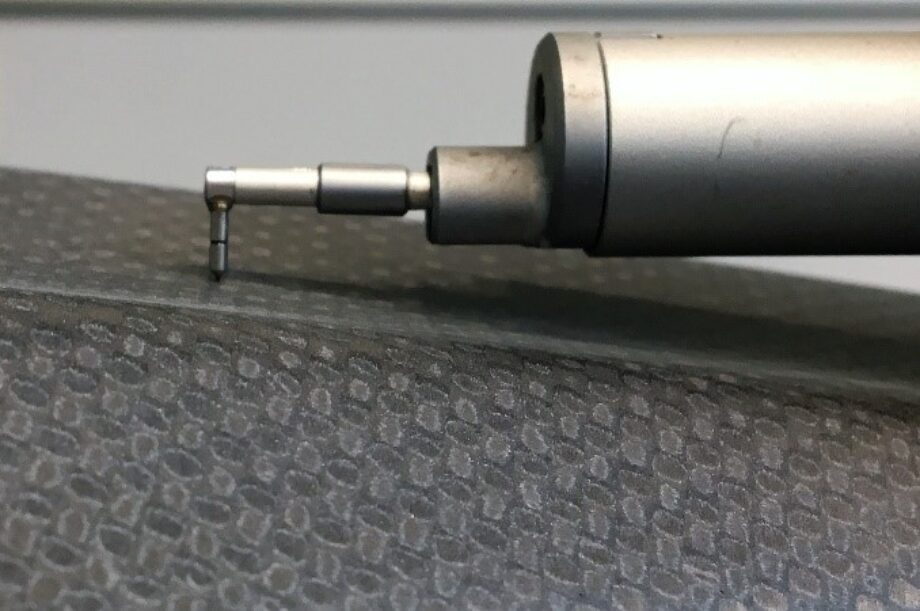

To overcome this problem, Norblast has invested in the design of state-of-the-art surface activation equipment, which enables the surface of composites to be treated in a meticulous and careful manner.

With Norblast’s surface activation equipment, it is possible to:

- Reduce processing times per individual component by up to 10 times;

- Achieve any type of surface, regardless of the shape of the material, undercuts, cracks or coves without risking damage to the part;

- Guarantee the uniformity of the parts produced: the first machined part always has the same characteristics as the last;

- Dramatically reduce production errors and the number of damaged parts;

- Reducing operator dependency: being performed by a machine, processing does not depend on the skills of a single individual. This makes it possible for the company to guarantee a constant production capacity at all times.