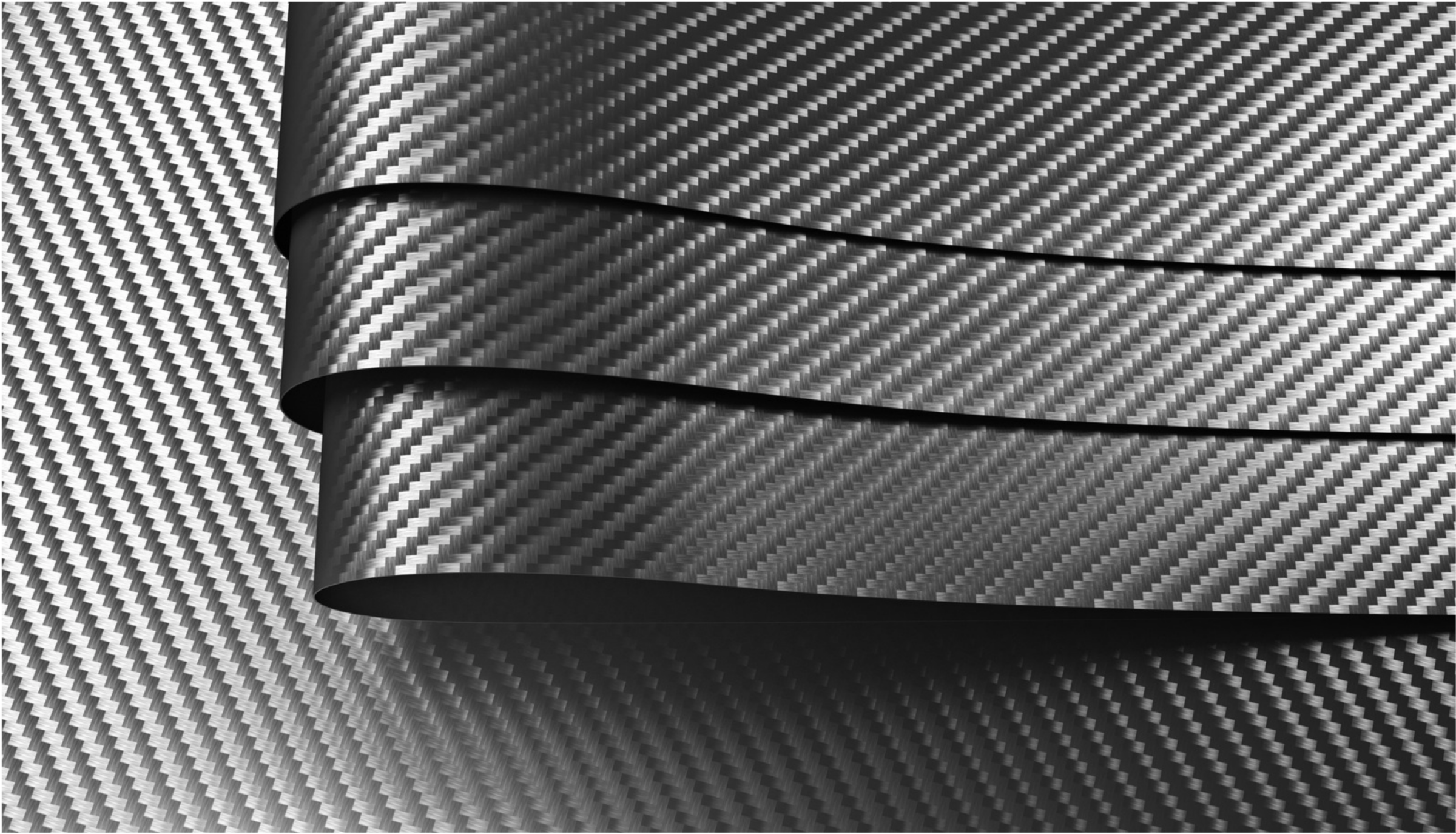

Due to their light weight, strength and durability, carbon and composite materials are being increasingly utilised for the production of high-quality items.

High-precision industries such as the automotive, aerospace, biomedical and precision engineering sectors depend on these materials to manufacture advanced components that demand highly accurate finishes for top performance and a long service life.

For this reason, sandblasting treatment on composites plays a vital role, enabling the material to be processed with the utmost care while maintaining its mechanical properties intact.

Sandblasting is ideal for enhancing the adhesion of subsequent protective or decorative coatings, ensuring the material remains unaltered and undamaged. At Norblast, we have developed cutting-edge solutions specifically for the treatment of carbon and composites, allowing these materials to be processed with precision, and without harming their surfaces.

Using advanced technologies and machinery specifically designed for composites, Norblast delivers targeted treatments that enhance component performance, ensuring exceptional quality and durability.

We offer advanced sandblasting and shot peening technologies, utilising state-of-the-art machines that provide precise control over the process parameters. These sophisticated systems allow for the adjustment of pressure, grit type and speed, adapting to the specific characteristics of the carbon and composite materials to prevent any scratching or deformation.

The safety of the treated material is a top priority, with each stage of the process being carefully monitored to avoid surface damage and maintain the structural integrity of the composite material.

Thanks to a broad range of options, we are able to fine-tune each treatment, delivering a high level of precision and a uniform finish without compromising the material’s structure.

We thoroughly assess each customer’s requirements, offering tailored solutions optimised for both the industry and the specific material, while always ensuring high-quality results.

Thanks to our in-house laboratory, we are able to test our solutions directly on customer-supplied samples, allowing you to witness the precision of our equipment first-hand.

We offer ongoing support to ensure continuous production, responding promptly to any requests and supporting you throughout every phase.